The need for premium PCB fabrication and assembly has risen, leading to the development of many PCB manufacturers across the globe. The diversity in types of circuit boards, such as flexible PCBs, rigid-flex circuit boards, and high-density interconnect (HDI) PCBs, provides to the diverse requirements of markets ranging from consumer electronics to telecoms.

A printed circuit board is basically a slim board made from a non-conductive product, such as fiberglass, to which pathways and connections for electronic components are printed or etched. Their design and assembly are vital, and companies that concentrate on PCB assembly frequently give a variety of services consisting of prototyping, production, and assembly of these vital components. By making use of advanced PCB manufacturing methods, manufacturers are qualified of producing circuit card that meet the rigid needs of high-frequency applications, such as those found in superhigh frequency (RF) communication circuits. This consists of the competence to design and fabricate high-frequency PCBs that can manage the complex characteristics of RF circuits, a vital facet of today's communication modern technology.

The process of PCB assembly generally entails several key stages, including soldering components to the PCB, testing for high quality guarantee, and making certain the last item satisfies both governing criteria and customer specifications. Additionally, the increase of quick turn PCB services has significantly decreased the lead time for manufacturing circuit boards, permitting companies to innovate faster and bring products to market more promptly.

When it comes to PCB fabrication, manufacturers might provide a variety of choices, from common FR-4 products to sophisticated products like Rogers 4350B and Megtron 6, which are made for high-performance applications. Each material brings its very own set of benefits, such as boosted thermal conductivity and reduced signal loss, making them ideal for details applications in sectors such as aerospace, clinical, and vehicle sectors. Additionally, the capabilities of manufacturers have increased to consist of not only conventional PCB assembly but additionally custom PCB remedies, permitting businesses to bring their special designs to life. Custom PCB fabrication services allow customers to specify the specific measurements, layer count, and materials required for their task, making sure compatibility with a variety of electronic designs.

Flex PCBs, or flexible printed circuits, stand for an additional specialized location within the PCB sector. These boards can flex and turn, making them optimal for applications where space is restricted or where typical rigid boards may not fit. The advancement of flexible PCB technology has opened up new opportunities in item design, particularly in smart phones, wearable modern technology, and clinical tools. Flexible circuit card frequently feature the benefits of light-weight building and construction, lowered room demands, and the ability to incorporate numerous functions within a single device, making them a preferred choice amongst developers and engineers.

The manufacturing of multilayer circuit boards, which comprises numerous layers of circuitry piled with each other, has actually become increasingly widespread. These multilayer boards are essential for complicated electronic devices that need a high level of integration and density. Successful multilayer PCB assembly demands precise alignment and careful consideration during the design phase to avoid signal interference and ensure optimal efficiency. The difficulty of building top-tier multilayer circuit card usually depends on producing vias-- small plated holes that permit electrical links between the various layers. Advanced methods, like blind and buried vias, have arised to satisfy these complexities without endangering the performance and capability of the PCB.

Another crucial consideration in PCB engineering is impedance control, which is essential for guaranteeing signal honesty, particularly in high-speed applications. Engineers have to thoroughly assess the physical layout of circuit traces, the product residential properties of the PCB, and the connection methods to maintain consistent impedance throughout the board. Integrating these principles right into PCB design not just enhances performance however additionally adds to the integrity of communication circuits and high-frequency applications.

For companies wanting to enhance their PCB production process, turnkey PCB assembly services can be an ideal service. These services envelop all stages of production from fabrication to assembly and testing, under one umbrella. This technique not just minimizes the time called for to turn design principles right into finished products yet additionally streamlines supply chain management by lowering the demand for multiple suppliers. The capacity to get all components and assembly services from a solitary source improves effectiveness and can lead to cost savings, particularly for high-volume production needs.

The competitors among PCB manufacturers has led to an enhanced focus on top quality and advancement, with lots of firms implementing rigorous top quality control procedures to guarantee their circuit card fulfill market criteria. Accreditations like IPC-A-610, which controls the acceptability of electronic assemblies, play a crucial role in guaranteeing consumers of the dependability and longevity of their items. Manufacturers should count on advanced evaluation technologies, such as automated optical examination (AOI) and X-ray analysis, to find issues early in the production process, therefore reducing waste and enhancing overall product quality.

The environmental effect of PCB production has also come to be a considerable problem in the last few years. As organizations become a lot more environmentally mindful, PCB manufacturers are embracing sustainable practices, consisting of making use of environment-friendly products and the application of waste decrease initiatives. Furthermore, laws pertaining to the disposal of electronic waste, such as the European Union's RoHS instruction, have affected manufacturers to minimize making use of hazardous compounds in their items, cultivating an industry-wide change toward greener production techniques.

In the world of technology, recent innovations in PCB modern technology have introduced amazing possibilities. As electronics continue to advance, so as well does the relevance of innovative techniques to PCB design and manufacturing.

Small-scale prototyping has likewise developed significantly, allowing companies to examine designs rapidly prior to devoting to larger production runs. Prototyping not only enables designers to determine possible design problems however also provides a possibility for optimization, making it possible for customized adjustments that can make a considerable difference in the final performance of an electronic tool. The ability to deliver high-grade prototypes in a brief timeframe enhances the rapid pace of item advancement that identifies today's innovation landscape.

As need for electronic gadgets remains to escalate, the requirement for innovative PCB remedies will only expand. The rich range of PCB designs, varying from circuit card assemblies to specialized high-frequency designs, underlines the vital duty that these boards play in allowing the capability of contemporary electronics. With ongoing advancements in manufacturing innovations, flexible designs, and product sciences, the future of PCB production looks encouraging. Continued partnership in between end-users, manufacturers, and developers will be important in driving the following generation of advancements that will shape the electronic landscapes of tomorrow.

In verdict, from the standard motherboard to the extremely sophisticated multilayer designs and flexible circuits that adapt to innovative applications, printed motherboard stand for the core of electronics. The adaptability, integrity, and performance of these components consistently drive sectors to look for out superior capacities in PCB manufacturers. With the most current developments in technology, the production of PCBs is coming to be much more reliable, environmentally pleasant, and customized to the developing needs of a significantly electronic world. As we look in advance, the combination of new products, designs, and fabrication techniques will most certainly play a critical role in transforming just how we interact with innovation, leading the means for revolutionary electronic applications in the years to find.

Check out custom printed circuit board manufacturers the central role of printed motherboard (PCBs) in modern electronics, from multilayer and flexible designs to lasting manufacturing methods, and find just how developments in innovation are shaping the future of PCB production.

Haley Joel Osment Then & Now!

Haley Joel Osment Then & Now! Michelle Pfeiffer Then & Now!

Michelle Pfeiffer Then & Now! Kelly Le Brock Then & Now!

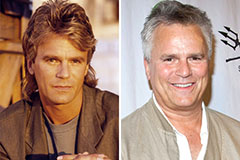

Kelly Le Brock Then & Now! Richard Dean Anderson Then & Now!

Richard Dean Anderson Then & Now! Terry Farrell Then & Now!

Terry Farrell Then & Now!